MEDICAL VACUUM PLANT

ANAESTHETIC GASES

In healthcare, the most widely used anaesthetic gases are: • nitrous oxide (N2O), • halogenated an-aesthetics (halothane/Fluothane, enflurane/Ethrane, isoflurane/Forane, sevoflurane/Sevorane) as vola-tile liquids, which are vaporised by mixing them in different percentages with other gases (generally, 40% oxygen + 60% nitrous oxide): • ¾ halothane: 50 ppm, equalling 400 mg/m3; • ¾ enflurane: 75 ppm, equalling 575 mg/mcpp; • ¾ sevoflurane: 2 ppm, equalling 16 mg/m3; • ¾ isoflurane: 75 ppm (2 ppm, when used with N2O); • ¾ N2O: 50 ppm, equalling 91 mg/m3 for new or renovated operation theatres, 100 ppm for pre-existing operation theatres.

The “controlled contamination ventilation and conditioning system” (VCCC) must provide ventilation to environments suitable for maintaining the environmental concentrations of anesthetic agents, and/or other gaseous pollutants, below the pre-established limits. However, the installation of a VCCC system still requires a central scavenging disposal system for anaesthetic agents, with special active evacuation systems on anesthesia devices.

ANAESTHETIC GAS SCAVENGING

Healthcare facilities require a continuous supply of medical gases and medical vacuum. The constant functioning of anaesthetic gas scavenging system is as important to ensure patients’ safety and reduce the exposure of healthcare professionals. The UNI Standard 11100:2011 regulates the use and the management of gas pipeline systems and anaesthetic gas scavenging systems, including all possible updates. The Standard mainly addresses healthcare facilities and points out the need for this type of equipment to guarantee safety and efficiency during its whole life cycle.

The UNI Standard 11100 complements UNI EN ISO Standard 7396-1 (“Medical gas pipeline systems – Pipeline systems for compressed medical gases and vacuum”) and UNI EN ISO Standard 7396-2 (“Medical gas pipeline systems – Anaesthetic gas scavenging systems”).

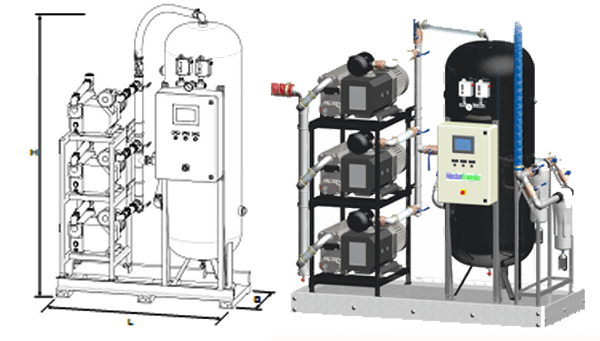

The medical vacuum systems manufactured by Master Energia complies with Directive 93/42/CEE and pre-sents all technical requirements established by national and international standards. Regardless of the manufacturing site where they are produced, all components undergo thorough checks. Then, they are assembled in-house and tested. All medical devices manufactured by the company are CE marked, in compliance with the quality requirements indicated in EN ISO Standard 13485.

A scavenging system includes a vacuum generator to start the system, a pipeline system and one or multiple terminal units. Specific relief valves for waste gas are connected to the anaesthetic gas suction system.

An active scavenging system is to be preferred over a passive one. In compliance with UNI EN Standard 7396, the medical vacuum system consists of a primary and a secondary vacuum pump, an emergency vacuum pump and a tank to make sure the flow is always constant and pulse-free.

In medical applications, the degree of vacuum requested is quite low.

Medical vacuum employs almost the same methods and equipment used in industrial vacuum systems. Yet, it is produced according to the harmonised EN ISO Standard 7396-1 and to the way the norm applies to central vacuum systems for surgical endocavitary suction.

The main difference lies in the high levels of hygiene the system needs to guarantee. It features special antibacterial filters, which trap the widest range of impurities. Another prerequisite of medical vacuum systems is the use of different auxiliary emergency systems: secondary pumps and filters are activated automatically in case of failure in the primary elements. Stainless steel AISI 316L is the ideal material to guarantee high standards of hygiene: unlike other materials, it is neutral and bacteria do not proliferate over steel surfaces. Central Medical Vacuum Supply System is used to provide a reliable and continuous suction in various departments of a hospital, such as operation theater, intensive care- unit, coronary and neonatal care-unit, delivery and emergency departments and patient wards.

MEDICAL VACUUM PLANT